MADE-TO-ORDER SOLUTIONS FOR CORE AND MOLD PRODUCTION

Core manufacturing technology

- Automatic core shooters and core shooters for Cold Box, CO², SO², Hot Box, Croning (sand shell molding) and inorganic processes with a core weight from 3.5 kg to 200 kg,

- Automatic core shooters with a robot,

- Transfer systems,

- Core sand preparation systems with vertical high-speed mixers and rotary blade mixers for the automatic preparation of core sand mixtures ready for shooting, organic or inorganic core sand mixtures,

- Centralized or decentralized amine supply, and

- Steelwork.

Molding technology - green sand

- Fully automatic flask-mounted molding plant,

- Mechanical molding plant,

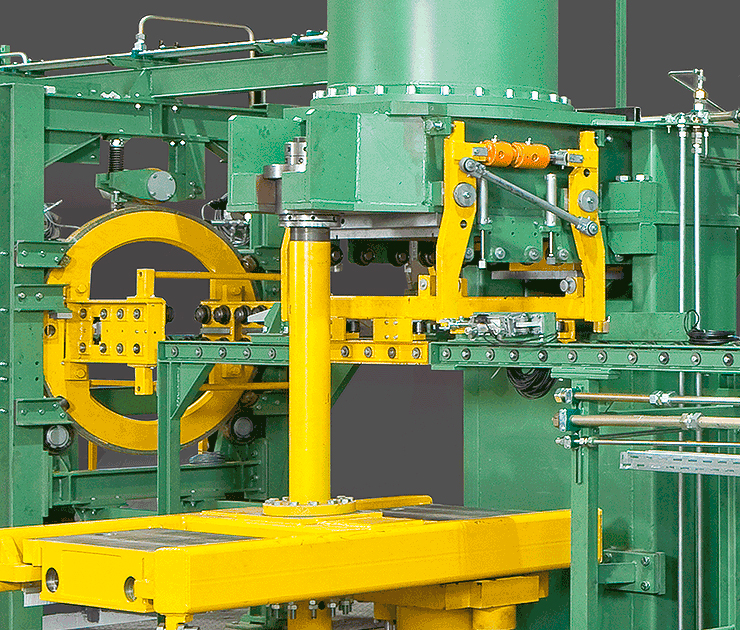

- Pulse molding machines,

- Jolt-squeezing molding machines,

- Systems for molding material preparation, aerators, screening systems, conveyor systems, bunker systems, batching plant for aggregates, and

- Molding material rotary mixers.

Molding technology - cold-setting molding sands

- Stationary continuous mixers with a preparation capacity of 3 to 60 t/h for the continuous preparation of molding materials in the no-bake molding process, on furan, phenol or polyurethane basis, inorganic molding materials on a water glass basis,

- Peripheral equipment for automatic mold circulation,

- Vibrating tables, and

- Mechanical molding material regeneration.

Coating equipment

- Dip tanks and flooding basins,

- Handling systems,

- Centralized black wash receipt,

- Equipment-related handling for the automatic dipping of cores.

THIS IS HOW WE WORK:

VIEDO OF A MOLDING PLANT BUILT BY US.

Pulse molding machine with cope and drag, turning and off-loading device, transfer truck to the forming line, feeding device to separate the molding boxes and pallets plus emptying device and separator.