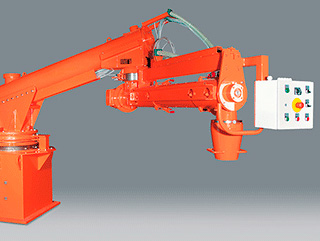

MOLDING TECHNOLOGY - COLD SETTING MOLDING SAND - CONTINUOUS MIXERS

Continuous mixers of the CM 15-60 series are designed for the continuous preparation of molding materials in the no-bake process on a furan, phenol or polyurethane basis. They can also be used for organic molding materials on a water glass basis. Continuous mixers of the CM 3-8 series are designed for making cores and molds.

Special features:

- Proven and tested mixers for the homogeneous preparation of molding materials while maintaining a high level of wear resistance,

- Easy to maintain owing to trough bowls hinged for sideways opening, with quick-acting fasteners,

- Mixers fitted with wear liners of high stability under load,

- Mixing screw with adjustable mixing vane base bodies and screwed-on mixing vane attachments for wear protection, permanent mold casting for very long service life; mixing vane inserts designed for easy replacement,

- Driven by an electric motor with soft start of the swivel joints, as an option,

- The sand is fed to the mixer via an enclosed conveyor belt for fast sand change,

- Infinitely adjustable sand flow rate via a sand gate valve with electromagnetic control,

- Switchover of the preparation throughput via a step switch on the control box,

- Frequency-controlled pumps feed the binder systems to the mixer controlled via limitation of the flow rate; here, the flow rate is monitored at the metering valves,

- System control via PLC control in "Automatic" or "Manual" modes, programs are available for sand or binder volumetric calibration, and

- Control via radio remote control as an option.